Tips on Using an Electric Buffer

Overview

We all love how clean and shiny a vehicle looks after a good clean and polish - but a lot of us don't have the time. An electric buffer can help speed up this process, along with quality products to help keep that shine for longer.

Like any power tool, it takes a little time to get comfortable and build up a technique when using polishers. Make sure you practice on a piece of scrap before moving over to your vehicle.

The Rotary Buffer is designed to heavily cut the surface paint. It is great for eliminating swirls, scratches and paint defects but is more prone to causing paint damage.

The Random Orbital Buffer varies the point of contact to minimise the risk of damage. However, Random orbital buffers are only suited for removing light paint swirls and blemishes. It has little effect on scratches and paint defects.

Before you start, ensure you are working in a well-lit area. Good lighting will allow you to see swirling, scratches and defects clearly.

Steps

Apply Polish

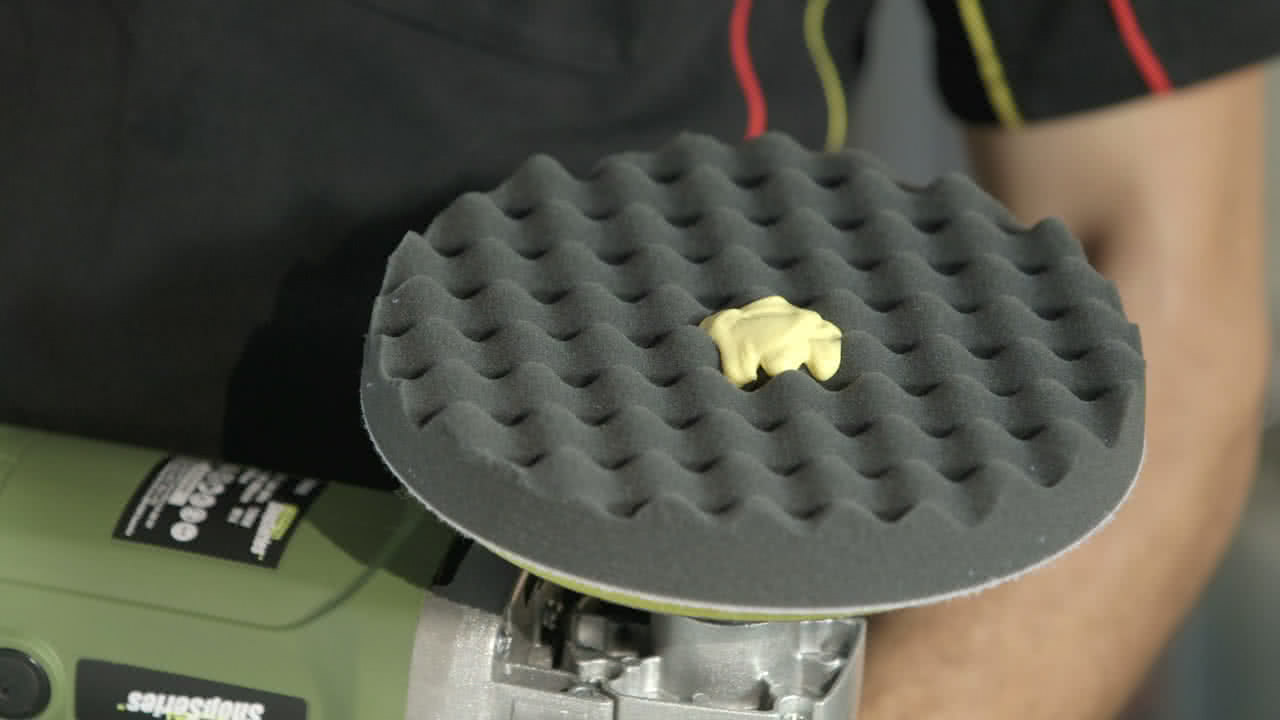

Once the panel is dry apply a small dab of polish to the applicator pad.

Work Polish into Panel

Place the buffer onto the panel and spread the polish before switching it on.

Move the buffer constantly in an overlapping motion left to right and up and down

Work In Sections

Start with a low speed of rotation and slowly increase the speed but stay within the lower speed ranges to prevent damage.

Buffers only require a light pressure to work. Keep your touch light.

Work in small sections completing one before moving on to the next.

A light spray of quick detailer onto the pad can make application easier.

Buff to a Shine

When the polish beings to dry or turn clear use a micro fibre cloth to remove the residue. Inspect the results and if you are satisfied move onto the next section.

*Important information* - Click here to read more about our DIY Advice Terms and Conditions.